The challenge: High requirements!

Clients demand clean welds! There may not be any oxygen around the welding zone inside the pipe as this will cause damage to the surface of the material, which will erode faster and provide a breeding ground for bacteria.

The pipes must be able to drain, which is why the weld may not be convex/concave as this leaves product residue at the weld.

The solution: High quality!

The OxyGone welding system makes it easy to meet the requirements! When argon/forming gas is guided in through the pads, the oxygen is pushed away quickly without generating any over-pressure in the welding zone, which makes the weld all smooth and glossy.

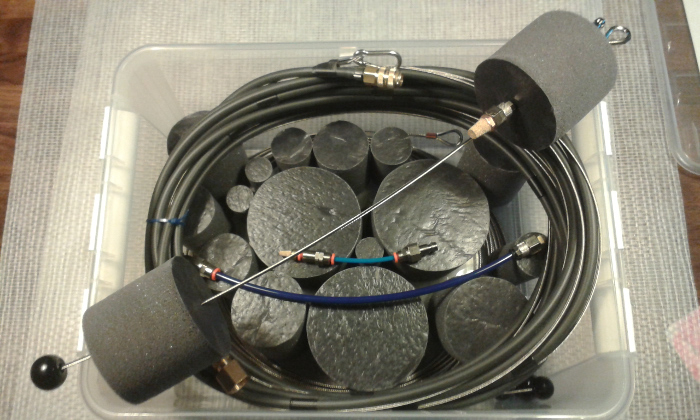

Gas coverage set

The gas coverage set consists of the following:

- 10-metre hose fitted with wire, snap hook and quick coupling

- 3 pulling stations

- 3 gas nozzles

- 18 pads in 6 different sizes for either dairy or inch pipes:

- dairy pipe sizes

- Ø 25 mm

- Ø 38 mm

- Ø 51 mm

- Ø 63 mm

- Ø 76 mm

- Ø 101 mm

- inch pipe sizes

- Ø 33 mm

- Ø 48 mm

- Ø 60 mm

- Ø 76 mm

- Ø 89 mm

- Ø 114 mm

- 10-metre rigid stainless steel feed wire

- Storage box in plastic

- Hoses can be coupled together if they need to be longer than 10 metres.